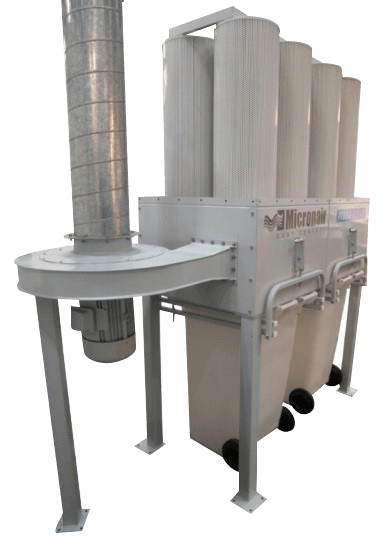

Dust Extraction

Why do we need dust extraction systems?Dust extraction is a critical aspect of maintaining a safe and efficient working environment in various industries. The accumulation of dust can pose serious problems, ranging from health hazards to operational inefficiencies. Installing a dust extraction system not only addresses these issues but also brings about a myriad of benefits. In Australia, adherence to specific standards is crucial to ensure that workplaces meet the necessary safety and environmental regulations.

Problems Caused by Lack of Dust Extraction

The absence of a dust extraction system can lead to a host of problems, impacting both the health of workers and the efficiency of industrial processes. One of the primary concerns is respiratory health. Fine particulate matter present in dust can become airborne, posing a significant risk to individuals who inhale it regularly. Prolonged exposure may lead to respiratory diseases such as asthma, bronchitis, and even more severe conditions like pneumoconiosis.

Moreover, dust accumulation in industrial settings can compromise the performance of machinery and equipment. Dust-laden environments may cause overheating, increased wear and tear that lead to reduced operational efficiency. This not only results in higher maintenance costs but also poses safety risks due to potential equipment malfunctions.

Worker Health and Safety

Perhaps the most crucial benefit of a dust extraction system is the protection of workers’ health. By removing airborne particulates, the system ensures that employees are not exposed to hazardous dust, significantly reducing the risk of respiratory ailments.

Increased Operation Efficiency

Dust-free environments contribute to the optimal functioning of machinery and equipment. A dust extraction system prevents the accumulation of particles on surfaces and moving parts, minimizing wear and tear, and extending the lifespan of industrial equipment. This leads to improved operational efficiency and reduced downtime.

Compliance with Environmental Regulations

Dust extraction systems play a pivotal role in ensuring that industrial activities adhere to environmental standards. Many jurisdictions, including Australia, have stringent regulations regarding air quality and emissions. Installing an effective dust extraction system helps industries comply with these regulations, avoiding fines and legal complications.

Essential Requirements for Dust Extraction

In Australia, several standards govern the design, installation, and operation of dust extraction systems to ensure workplace safety and environmental compliance.

Additional essential considerations for dust extraction systems include:

Identifying and classifying areas where dust extraction systems will be implemented to determine the level of explosion risk and guide appropriate safety measures.

Ensuring that electrical components within dust extraction systems are designed and installed in accordance with safety standards, minimizing the risk of electrical hazards.

Establishing protocols for performance testing to verify that dust extraction systems effectively capture and remove particulates from the air.

Providing guidelines for the regular maintenance and inspection of dust extraction systems to ensure their ongoing effectiveness and compliance with safety standards.

Australian Standards for Dust Extraction

AS/NZS 3000 – Electrical Installations – Wiring Rules: and while it covers various aspects of electrical systems, including wiring, earthing and protection, it is applicable to 3-phase motors and industrial electrical components used within those installations.

AS/NZS 3008 – Electrical Installations – Selection of Cables: This standard specifies the requirements for selecting and sizing cables, including those used for 3-phase motors and other industrial equipment to ensure proper electrical distribution.

AS/NZS 3439 – Low Voltage Switchgear and Controlgear Assemblies: This standard covers the design, construction and testing of low-voltage switchgear and controlgear assemblies and their safe operation.

AS 60034 – Rotating Electrical Machines (Series): This standard specifically deals with rotating electrical machines, including 3-phase motors.

AS 2380 – Electrical Equipment for Explosive Atmospheres: This standard provides requirements for electrical equipment used in hazardous areas where flammable gases, vapors, or combustible dust may be present. It is relevant to certain industrial settings and specific motor installations where explosion protection is required.

IEC Standards – In addition to Australian and New Zealand standards, International Electrotechnical Commission (IEC) standards are often used as a reference for electrical components.

AS/NZS 1668.2:2012 – Focuses on ventilation design for controlling indoor air contaminants, including dust, in buildings. While providing key guidelines, it’s not specific to industrial dust extraction systems. For detailed requirements in heavy-duty industrial processes, it’s advisable to refer to industry-specific standards or seek an expert consultation. This standard is a component of broader indoor air quality management in industrial settings and professional advice is essential for designing and installing effective dust extraction systems.

AS 4312-2014 – Hazardous areas classification of flammable gases and vapours, combustible dusts and ignitable flyings.

AS/NZS 4745:2012 – Code of practice for handling combustible dusts

The installation of a dust extraction system is not merely a matter of operational convenience; it is a critical investment in worker health, safety, and environmental compliance. The problems caused by the absence of such systems are far-reaching, affecting both human well-being and industrial efficiency. By adhering to Australian standards companies can ensure that their dust extraction systems are designed and operated in a manner that aligns with the highest safety and environmental benchmarks, thus creating a healthier and more productive workplace.