Fume Extraction

Why do we need fume extraction systems?Fume extraction plays a pivotal role in maintaining a safe and healthy work environment, particularly in industries where the production processes generate airborne contaminants. Without proper fume extraction systems in place, workplaces can face a myriad of issues that not only compromise the health of workers but also impact productivity and compliance with safety regulations. This article delves into the problems associated with the absence of fume extraction, explores the benefits of installing a dust extraction system, and references relevant Australian standards that guide industry practices.

Problems Caused by Lack of Fume Extraction

Not having a fume extraction system in a business, especially in industries that involve processes such as welding, painting, or other activities that generate harmful fumes, can lead to several problems.

The absence of a fume extraction system in a business can lead to a myriad of problems that compromise both the well-being of employees and the overall operational efficiency of the organization. One of the primary concerns is the adverse impact on employee health. Without an effective fume extraction system, workers are exposed to harmful airborne contaminants generated during various industrial processes, such as welding, soldering, or chemical manufacturing. Prolonged exposure to these fumes can result in respiratory issues, irritation of the eyes and skin, and long-term health complications. Moreover, the compromised health of employees can lead to increased absenteeism, reduced productivity, and higher healthcare costs for the business.

In addition to the health implications, the absence of a fume extraction system can pose a serious threat to workplace safety. Accumulation of noxious gases and particulate matter in the air can create an environment prone to accidents and fires, thereby increasing the risk of workplace injuries and property damage. Furthermore, the lack of proper fume control can contribute to the deterioration of equipment and machinery, leading to increased maintenance costs and operational downtime.

From a regulatory standpoint, failure to implement adequate fume extraction measures may result in non-compliance with environmental and occupational health and safety regulations. This can expose the business to legal consequences, fines, and reputational damage. Customers, suppliers, and other stakeholders may view the company unfavourably, affecting its standing in the industry and potentially leading to a loss of business opportunities.

Health Hazards

One of the primary concerns associated with the absence of fume extraction is the exposure of workers to hazardous airborne pollutants. These contaminants, which can include dust, fumes, and gases, pose serious health risks when inhaled. Prolonged exposure may lead to respiratory issues, allergic reactions, and even long-term illnesses.

Reduced Productivity

Accumulation of dust and fumes in the workplace can hinder productivity. Machinery and equipment may suffer from decreased efficiency and increased wear and tear due to the abrasive nature of certain particles. Additionally, the need for frequent cleaning to maintain a safe environment can disrupt workflow and reduce overall efficiency.

Fire and Explosion Risks

Certain industries generate combustible dust and fumes, which, in the absence of proper extraction, can pose significant fire and explosion hazards. The accumulation of combustible materials in confined spaces can lead to catastrophic incidents, jeopardizing both personnel and property.

Benefits of a fume extraction system

The foremost benefit of installing a fume extraction system is the significant improvement in indoor air quality. By effectively capturing and removing airborne contaminants at the source, these systems prevent the buildup of pollutants that can otherwise compromise the health and well-being of workers.

Fume extraction systems play a crucial role in ensuring the safety of workers by minimizing exposure to harmful substances. This, in turn, reduces the risk of occupational illnesses, respiratory issues, and other health complications associated with prolonged exposure to hazardous fumes and dust.

Proper fume extraction not only protects the health of workers but also safeguards machinery and equipment. The reduction of abrasive particles in the air helps prevent premature wear and damage to vital components, thereby extending the lifespan of industrial equipment.

Australia has established stringent safety standards to protect workers and ensure the well-being of individuals employed in various industries. Compliance with standards such as AS/NZS 1715:2009 (Selection, Use, and Maintenance of Respiratory Protective Equipment) and AS/NZS 60079.10.1:2021 (Explosive Atmospheres – Electrical Installations) is crucial for companies to meet regulatory requirements and create a safe working environment.

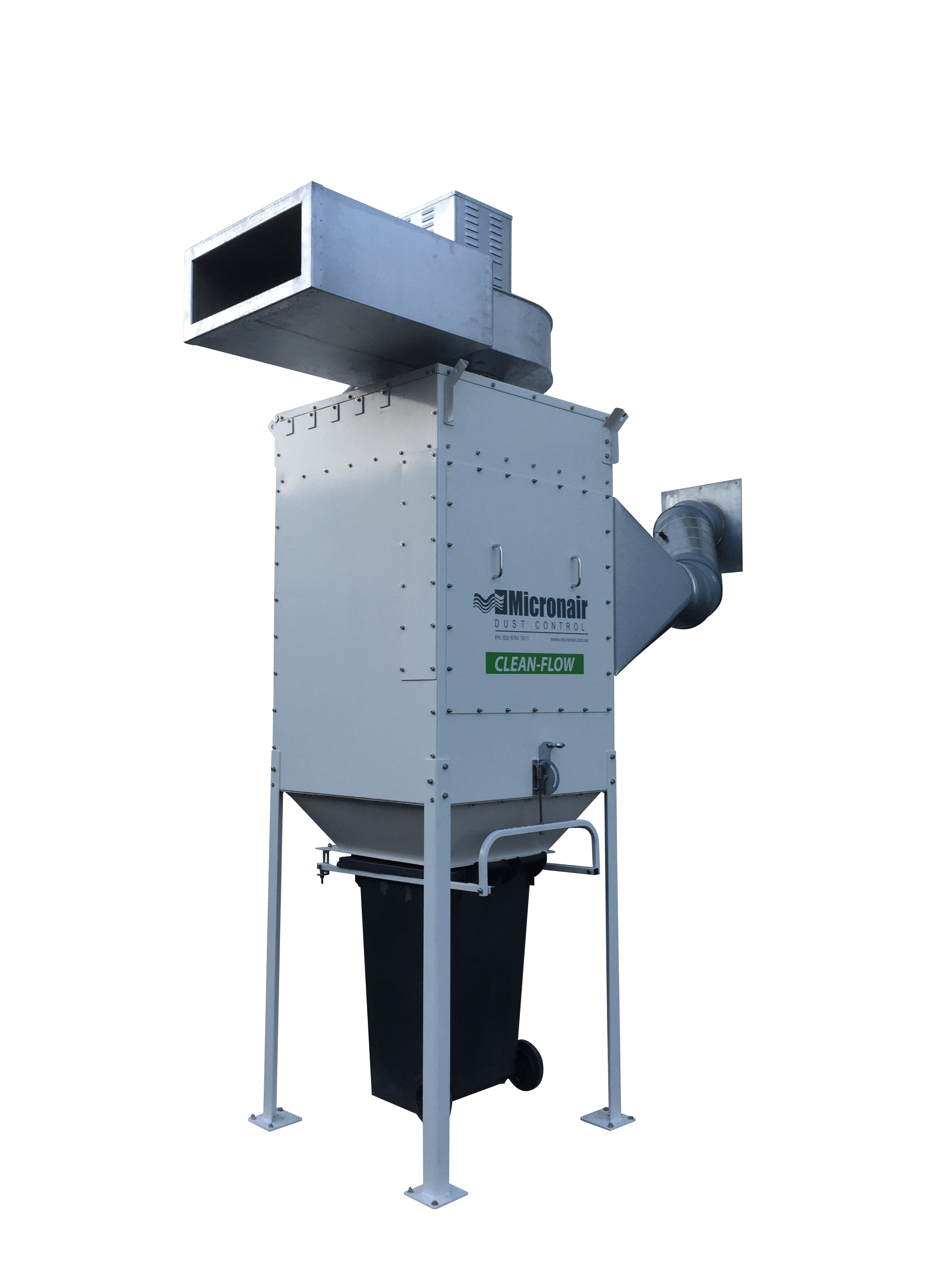

The installation of a fume extraction system is imperative for maintaining a safe, healthy, and productive workplace. The absence of such systems can lead to a myriad of problems, ranging from health hazards to fire risks and reduced productivity. Micronair is here to help with design, configuration and maintenance of a proper fume extraction system so that businesses not only prioritize the well-being of their employees but also ensure compliance with Australian safety standards, promoting a culture of responsibility and accountability.