About us

Our story at MicronairHumble beginnings

Micronair was formed to service the woodworking industry and help provide a safe working environment for employees. From there it has grown to service multiple industries from government, manufacturing, education and so much more. Micronair now provides a range of solutions to air quality and extraction challenges.

Exceeding standards

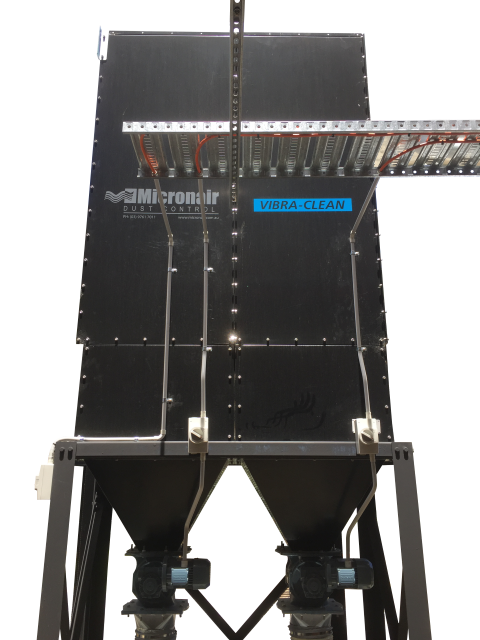

With today’s major health concerns over inhalable toxins, it is critical that manufacturers address these issues created with traditional bag collectors that provide only 95% efficiency. Micronair aims for a minimum of 98% and up to 99.9% efficiency by incorporating our advanced filter cleaning methods, and only using high efficiency filter media of minimum E12 standard.

Continuous improvement

Micronair has adopted a continuous improvement process throughout the company, especially in the area of research and development of better filtration products. Micronair’s research and development program has produced products that are advanced beyond the industry standards.

A family business

We take pride in our work and manufacture our products to exceed Australian requirements.

Made in Australia means that parts required for servicing or in the case of emergency, are readily available to minimise downtime.

Protecting workers is a key purpose of extraction systems. Most filters on the Australian Market use filter bags with an average efficiency of 95%, this bleeds fine dust into the air. Micronair aims for a minimum of 98% up to 99.9% with high efficiency to deliver better protection.

Micronair goes beyond the standards, ensuring our units are a valuable long-term asset. Panels are made from galvanised metal that is then powder coated, fans are hot dip galvanised and we use stainless and aluminium fasteners for their anti-corrosive properties.

Senior Management Team

Don BreretonCEO

Don BreretonCEOFounder and CEO at Micronair, Don started the company and still runs it today with the support of his team.

Shannon BreretonSales Manager (NSW, QLD, NT)

Shannon BreretonSales Manager (NSW, QLD, NT)Shannon is a certified in electrotechnology and has been with Micronair over 10 years and relocated to grow the business and provide local expertise in Queensland.

Tony FarrellSales Manager (VIC, TAS, SA, WA)

Tony FarrellSales Manager (VIC, TAS, SA, WA)Tony has been with Micronair over 5 years and manages the southern team out of Melbourne.

Trent BreretonDesign & Development Manager

Trent BreretonDesign & Development ManagerTrent leads the development at Micronair and ensuring continuous improvement and working with the evolving Australian standards.

Lisa PerksProject Manager

Lisa PerksProject ManagerLisa manages the installation teams and works closely with the manufacturing teams to ensure unit delivery and installation.

Daniel LippProduction Manager

Daniel LippProduction ManagerWith component and unit manufacturing all in Melbourne, Daniel manages the teams and ensures supply meets demand for client projects.

Joshua DuffyInstallation Manager

Joshua DuffyInstallation ManagerWith some projects requiring complex installations or working with consultants, Joshua has years of experience working with delivery teams and manages the installation and service teams.

The future with Micronair

Micronair have time and again proven the ability to handle the particular and complex requirements that large customers have, from documentation to compliance, and emission verification with high performance criteria. Micronair’s design, engineering and experience proves invaluable when dealing with dust and fumes that have difficult characteristics such as sticky, oily, heavy chip, light flaking material, sharp, hydroscopic, acidic, super fine, this list and experience goes on. Our research has allowed us to develop highly efficient units with a low footprint to enhance the installation options while reducing duct lines and wasted costs.