Dust Control

Why do we need dust extraction systems?In today’s industrial and commercial environments, dust control is not just a matter of cleanliness but a vital aspect of maintaining a safe and efficient workspace. Excessive dust poses significant challenges to organizations, affecting the health of employees, the longevity of machinery, and overall productivity. Implementing effective dust control measures, particularly through dust extraction systems, is crucial in addressing these issues. This article explores the primary challenges posed by excessive dust, the role of dust extraction systems in mitigating these challenges, and the benefits of integrating these systems into organizational operations.

The Three Main Challenges Caused by Excessive Dust

The absence of a dust extraction system can lead to a host of problems, impacting both the health of workers and the efficiency of industrial processes. One of the primary concerns is respiratory health. Fine particulate matter present in dust can become airborne, posing a significant risk to individuals who inhale it regularly. Prolonged exposure may lead to respiratory diseases such as asthma, bronchitis, and even more severe conditions like pneumoconiosis.

Moreover, dust accumulation in industrial settings can compromise the performance of machinery and equipment. Dust-laden environments may cause overheating, increased wear and tear that lead to reduced operational efficiency. This not only results in higher maintenance costs but also poses safety risks due to potential equipment malfunctions.

Health Hazards

Excessive dust in the workplace can pose serious health risks. Employees exposed to high levels of dust can suffer from respiratory problems, allergic reactions, and in severe cases, long-term lung diseases. This is particularly prevalent in industries dealing with wood, chemicals, or fine particulates. Ensuring employee health is a primary concern for organizations, making the management of dust critical.

Equipment Damage

Dust accumulation can significantly shorten the lifespan of machinery and equipment. Sensitive components, such as motors and electronic systems, are particularly vulnerable to dust interference, leading to malfunctions and frequent maintenance needs. This not only increases operational costs but also disrupts the continuity of business operations.

Productivity Impact

A dusty environment can lead to a decrease in overall workplace productivity and efficiency. Excessive dust can cause frequent interruptions in production processes, requiring additional cleaning and maintenance. Moreover, an unclean environment can demotivate employees, further impacting their performance and efficiency.

Dust Extraction Systems for Dust Control

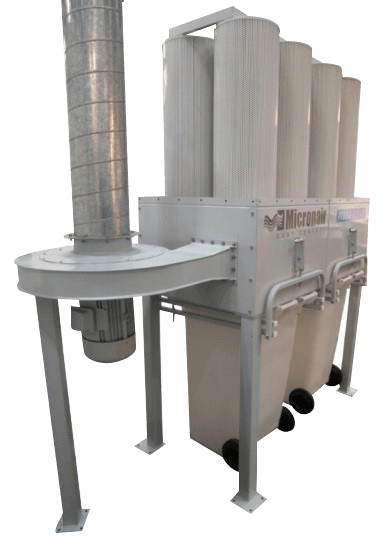

Dust extraction systems are engineered to control, collect, and remove dust from the workplace environment effectively. These systems typically consist of a network of pipes that transport dust from various points of origin, like machinery or processing areas, to a central extraction unit. This unit then filters and expels the dust, keeping the air clean and safe. By implementing these systems, organizations can drastically reduce the amount of dust in their facilities, directly addressing the challenges of health risks, equipment damage, and reduced efficiency.

One of the most significant benefits of a dust extraction system is the improved health and safety of employees. By actively removing harmful dust particles from the air, these systems create a cleaner, healthier work environment. This leads to fewer health-related absences, a lower risk of respiratory conditions, and a generally more pleasant working atmosphere. Moreover, compliance with health and safety regulations is greatly enhanced, protecting the organization from legal and financial repercussions.

Dust extraction systems play a vital role in protecting equipment and machinery from dust-related damage. By maintaining a cleaner environment, the wear and tear on machinery are significantly reduced, enhancing their longevity and performance. This results in lower maintenance costs, fewer equipment downtimes, and a higher return on investment in capital machinery. Moreover, the overall life span of the equipment is extended, allowing organizations to maximize the use of their assets.

A clean workplace is a productive workplace. Dust extraction systems contribute to maintaining a clean and efficient working environment, which in turn boosts employee morale and productivity. Workers are more likely to be motivated and focused in a clean, dust-free environment. Additionally, the reduced need for manual cleaning saves time and resources, allowing employees to concentrate on their core tasks. Cleanliness also makes a positive impression on clients and visitors, reflecting well on the organization’s operational standards.

Effective dust control through dust extraction systems is essential for any organization dealing with dust-related challenges. Micronair has dust extraction and dust control systems that offer comprehensive benefits, including improved health and safety, protection of equipment and enhanced productivity. Investing in a dust extraction system is an investment in the future of a business.