Changes to the workplace exposure standard for welding fumes

In a significant move to enhance workplace safety, Work Health and Safety (WHS) Ministers have agreed to an immediate reduction in the workplace exposure standard (WES) for welding fumes, which are not otherwise classified. The new WES lowers the 8-hour time-weighted average (TWA) from 5 mg/m³ to 1 mg/m³. This change, once implemented into WHS/OHS laws across the Commonwealth, states, and territories, mandates stricter control measures to protect workers from hazardous welding fumes.

Welding fumes contain various potentially harmful substances, including metals and their oxides. Prolonged exposure to these fumes can lead to serious health issues such as respiratory diseases and occupational asthma. The updated WES aims to mitigate these risks by significantly lowering permissible exposure levels. This regulatory change underscores the necessity for workplaces to adopt more stringent fume extraction and control measures to comply with the new standards and ensure worker safety.

Micronair’s Custom Solutions for Compliance

Micronair, a leading fume extraction supplier, is well-equipped to support industries in meeting the updated WES for welding fumes. With a strong commitment to workplace safety and innovation, Micronair offers a range of custom solutions designed to effectively manage and reduce welding fume exposure.

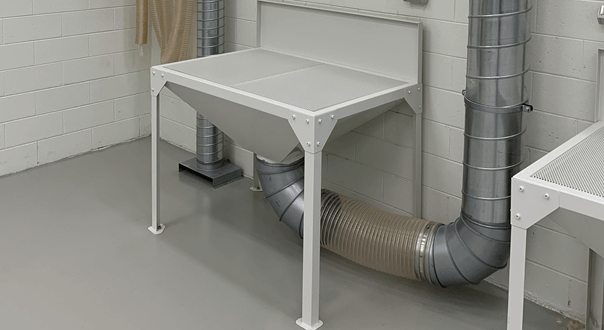

Advanced Fume Extraction Systems

Micronair’s advanced fume extraction systems are engineered to capture and filter hazardous welding fumes at the source. These systems utilize high-efficiency particulate air (HEPA) filters and other advanced technologies to ensure that airborne contaminants are effectively removed from the workplace environment. By deploying these systems, industries can achieve compliance with the new WES and significantly reduce the risk of health issues associated with welding fume exposure.

Micronair’s filters provide industry leading filtration that can clean down to one micron which is 1,000th of a millimetre.

Tailored Solutions for Diverse Needs

Recognizing that every workplace has unique requirements, Micronair provides tailored fume extraction solutions that cater to specific operational needs. Whether it’s a small workshop or a large industrial facility, Micronair’s experts assess the working conditions and customize the fume extraction setup to ensure optimal performance and compliance with the updated standards. This bespoke approach guarantees that all welding areas are adequately covered, providing comprehensive protection for workers.

Regular Maintenance and Support

To ensure the continued effectiveness of fume extraction systems, Micronair offers regular maintenance and support services. Routine checks and timely replacements of filters and other components are crucial for maintaining optimal system performance. Micronair’s dedicated service teams provide ongoing support to ensure that the fume extraction systems remain in top condition, thus continuously protecting workers from exposure to harmful welding fumes.

Commitment to Safety and Compliance

Micronair’s dedication to workplace safety is evident in its proactive approach to adapting to regulatory changes. By offering state-of-the-art fume extraction solutions and ongoing support, Micronair helps industries navigate the complexities of compliance with the new WES. Their expertise ensures that businesses not only meet regulatory requirements but also create a safer and healthier working environment for their employees.

The reduction of the WES for welding fumes marks a significant step towards improved workplace safety. Micronair’s custom fume extraction solutions are essential for industries seeking to comply with these new standards and protect their workers from the harmful effects of welding fumes. By investing in advanced fume extraction technology and expert support, businesses can achieve compliance and foster a safer, healthier work environment.