Australia Tightens Fume Exposure Standards

Australia’s workplace safety landscape is changing rapidly, especially for industries where welding is a key operation. In May 2024, Safe Work Australia made a significant decision by reducing the workplace exposure limit for welding fumes from 5 mg/m³ to 1 mg/m³. This new, stricter regulation underscores the need for more effective fume extraction solutions to... Learn More

Effective Fume Extraction in Australia’s Welding Industry

Welding is an essential trade in Australia, powering industries from construction to manufacturing. However, recent studies have raised serious concerns about the health risks associated with exposure to welding fumes, which contain hazardous particles that can cause long-term damage. Welding fumes, classified by the International Agency for Research on Cancer (IARC) as a known carcinogen,... Learn More

Safe Work Australia ban on engineered stone

The new regulations by Safe Work Australia mark a pivotal shift in the country’s approach to occupational health and safety. From 1 July 2024, the manufacture, supply, processing, and installation of engineered stone benchtops, panels, and slabs are prohibited across Australia. This sweeping ban aims to mitigate the health risks posed by respirable crystalline silica... Learn More

Changes to the workplace exposure standard for welding fumes

In a significant move to enhance workplace safety, Work Health and Safety (WHS) Ministers have agreed to an immediate reduction in the workplace exposure standard (WES) for welding fumes, which are not otherwise classified. The new WES lowers the 8-hour time-weighted average (TWA) from 5 mg/m³ to 1 mg/m³. This change, once implemented into WHS/OHS... Learn More

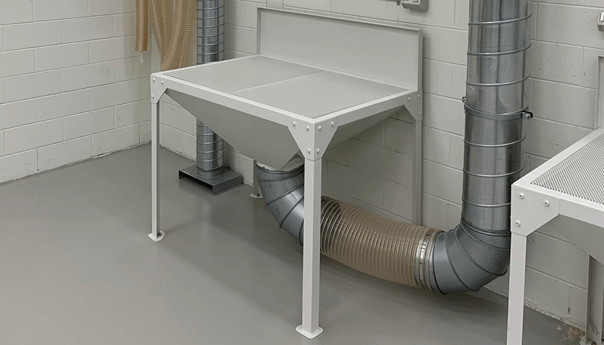

Servicing for high performance

With thousands of installations and over 80% of Micronair extraction units being used in the woodworking industry, servicing and maintenance will ensure your that extraction unit will keep it’s high level of performance. Regular servicing also looks beyond filters to other components of the system from ducting, hoppers and any other issues that could impact... Learn More

Next generation pleated filters

Historically pleated cartridge filters have been used in applications where high volumes of air are required with relatively low dust loads. This type of filter has been widely accepted throughout the world in many applications from food powders, welding fume, to mining applications. Traditionally the benchmark for this filter has been the pleated cartridge filter... Learn More

Silo storage and extraction

Micronair can now provide from Silo storage systems to handle difficult mixed dust and shavings. From design, manufacturing and installation these silo units can be with or without extraction units. The design allows for waste to be transferred into a high production briquetting system. This system can automate storage of dust and transfer to further... Learn More

Layers of sawdust building up?

Wood dust is a common byproduct of woodworking, and it is important to take the necessary precautions to protect your health and safety. Breathing in wood dust can lead to respiratory problems, allergies, and even cancer. That’s why it is essential to have a reliable air filtration system that effectively captures and removes wood dust... Learn More